Products

- Home

- Products

Our Products

Spur Gear

Spur gears are one of the most commonly used types of gears in the industry. They are used to transmit power and motion between two parallel shafts. Spur gears are cylindrical in shape and have teeth that are straight and parallel to the axis of rotation. They are designed to provide smooth and efficient power transmission.

Spur gears are widely used in various industrial applications, including in vehicles, manufacturing equipment, and machinery. They are known for their simplicity and reliability, making them a popular choice for many applications.

(Capacity till 12 Module)

Helical Gears

Helical gears are an essential component of many industrial applications. They are a type of gear that has angled teeth, which allows for a smoother and quieter operation compared to spur gears. Helical gears are commonly used in high-speed and heavy-duty applications where reliability and efficiency are critical.

One of the primary advantages of helical gears is their ability to transmit power smoothly and efficiently. The angled teeth of the gears allow for a larger contact area between the teeth, resulting in a smoother transmission of power. This results in less noise and vibration compared to spur gears, making them an ideal choice for applications where noise reduction is important.

(Capacity till 12 Module)

Internal Gears

Internal gears are a type of gear that has teeth on the inside of the cylinder. Unlike external gears, which have teeth on the outside of the cylinder, internal gears are designed to mesh with external gears. They are commonly used in applications where space is limited, and they offer several advantages over other types of gears.

One of the primary advantages of internal gears is their compact size. Because the teeth are on the inside of the cylinder, they take up less space than external gears, making them ideal for applications where space is at a premium. They are commonly used in planetary gear systems, where multiple gears are arranged around a central axis.

(Capacity till 12 Module)

Worm Gears

Worm gears are a type of gear that consists of a cylindrical screw-like gear (the worm) and a toothed wheel (the worm wheel). They are commonly used in applications where a large reduction in speed is needed, and they offer several advantages over other types of gears.

One of the primary advantages of worm gears is their ability to transmit power between perpendicular shafts. This makes them ideal for applications where space is at a premium, as they can be arranged in a compact manner. They are commonly used in heavy-duty applications such as conveyor systems, elevators, and heavy machinery.

(Capacity till 12 Module)nced and knowledgeable supplier who can help you choose the right gears for your needs.

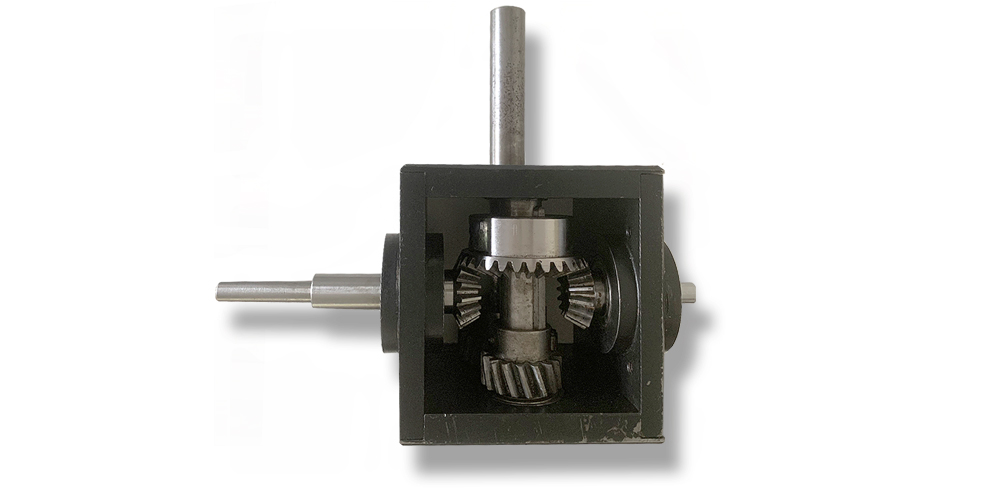

Bevel Gears

Bevel gears are a type of gear that has teeth that are cut at an angle to the gear’s face. They are commonly used in applications where two shafts intersect at an angle, and they offer several advantages over other types of gears.

One of the primary advantages of bevel gears is their ability to transmit power between non-parallel shafts. This makes them ideal for applications where the shafts intersect at an angle, such as in differential drives, automotive transmissions, and machine tools.

Another advantage of bevel gears is their ability to handle high loads. The angled teeth of the gears allow for a greater surface area of contact between the gears, which enables them to handle heavier loads without compromising their efficiency. This makes them a popular choice for heavy-duty applications such as mining, construction, and industrial machinery.

(Capacity till 12 Module)

Spiral Gears

Spiral gears are a type of gear that has teeth that are cut at an angle to the gear’s face and spiral around the gear. They are commonly used in applications where a high degree of accuracy, smoothness, and quiet operation are required.

One of the primary advantages of spiral gears is their ability to transmit power with minimal noise and vibration. The angled teeth of the gears allow for a gradual engagement, which results in a smoother and quieter operation compared to other types of gears. This makes them ideal for applications where noise reduction is a priority, such as in automotive transmissions, industrial machinery, and aerospace applications.

(Capacity till 12 Module)

Custom Gears

Custom gears are gears that are designed and manufactured to meet specific requirements and specifications for a particular application. These gears are often used in industries where off-the-shelf gears may not be suitable for the specific needs of the application.

One of the primary advantages of custom gears is their ability to meet unique requirements. By designing and manufacturing gears to specific specifications, they can be tailored to meet the specific needs of the application. This can include factors such as gear size, gear material, gear pitch, gear ratio, and more.

Rack and Pinion

A rack and pinion is a type of gear mechanism that is used to convert rotational motion into linear motion. It consists of a rack, which is a flat or curved bar with teeth along one edge, and a pinion, which is a small gear that meshes with the rack. When the pinion rotates, it moves the rack back and forth, providing linear motion.

Coupling

A coupling is a mechanical device that is used to connect two rotating shafts together. It is used to transmit torque from one shaft to another while allowing for a small amount of misalignment or movement between the two shafts. There are many different types of couplings available, including rigid couplings, flexible couplings, and universal couplings.

Chain Sprocket

A chain sprocket is a toothed wheel that is used to drive a chain. It consists of a central bore, which fits onto a shaft, and teeth along the outer edge that mesh with the chain. When the sprocket rotates, it pulls the chain along with it, transmitting power from one shaft to another.

Worm Shaft

A worm shaft is a type of gear mechanism that consists of a worm gear and a worm wheel. The worm gear is a cylindrical gear with a spiral thread that meshes with the teeth on the worm wheel. When the worm gear rotates, it moves the worm wheel, providing a high gear reduction ratio.

Screw Jack Gearbox

A screw jack gearbox is a mechanical device that is used to lift heavy loads. It consists of a motor, a gearbox, and a screw jack. The motor drives the gearbox, which in turn drives the screw jack, providing vertical motion. Screw jack gearboxes are commonly used in industrial applications, such as lifting heavy machinery and equipment.